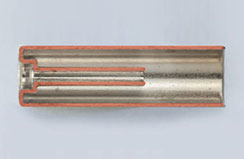

Deep Drawing

Features

The process specializes in thin-walled deep drawing, and can handle drawing depths of up to 37 times the outer diameter. We are also aggressively taking up the challenge of processing new materials, including brass, red copper, phosphorous deoxidized copper, tough pitch copper, beryllium copper, phosphor bronze, nickel-nickel, iron (SPCE, SPCC), stainless steel (SUS), plated steel plates, aluminum, nickel, and cladding. Today, we manufacture components in a wide range of industries, including the medical industry, telecommunications equipment, automobiles, and audio-related industries.

With Advanex

Products previously believed to be only machinable by cutting and pipe machining can also be commercialized by transfer machining and press machining. For example, we switched to transfer machining for products that had been machined, resulting in a four-fold increase in productivity and a substantial reduction in costs.

Case Studies

-

CASE 001

Electric Power Equipment Supply Manufacturer

-

CASE 002

Heavy Electrical Equipment Manufacturers

-

CASE 003

Plant Equipment Manufacturer

-

CASE 004

Plastic Parts Manufacturer

-

CASE 005

Medical Equipment Manufacturer

-

CASE 006

Antenna Manufacturer

-

CASE 007

Switch Manufacturer

-

CASE 008

General Electrical Equipment Manufacturer

-

CASE 009

Switch Manufacturer

-

CASE 010

Bearing Manufacturer

-

CASE 011

軽量天井業界